In this final installment of this 3-part series, we look at how the practices and principles of Lean IT provide the approach and tools needed to eliminate data quality issues at the source. See Part 1 here and Part 2 here.

For a practical example of Lean IT and data management, see the webinar Lean IT: Driving SAP Continual Process Improvement.

Lean IT as Part of the Solution

In lean, all improvement starts with the people. The first step is to engage with your employees by leading with respect, creating a meaningful challenge, and fostering a workplace where excellence is the norm. When you engage with people respectfully, they respond in ways you never could have dreamed plausible.

Bad data entered into high-performance IT systems produces what one CEO described as, “Crap at the speed of light!” Even if we successfully create a lean application development environment, bad data will efficiently yield inaction-able information and over time, people will disengage and lose trust in their leaders, as well as the ERP system. The resourcefulness and genius of most workforces lies dormant beneath layers of distrust, uncertainty, and unreliability of the systems they are forced to contend with.

You engage with people because they really are your most valuable resource; in fact, people are your only appreciative resource! It is those who are closest to the work (as well as closest the problems) that most deeply understand the challenges and are best positioned to develop effective countermeasures.

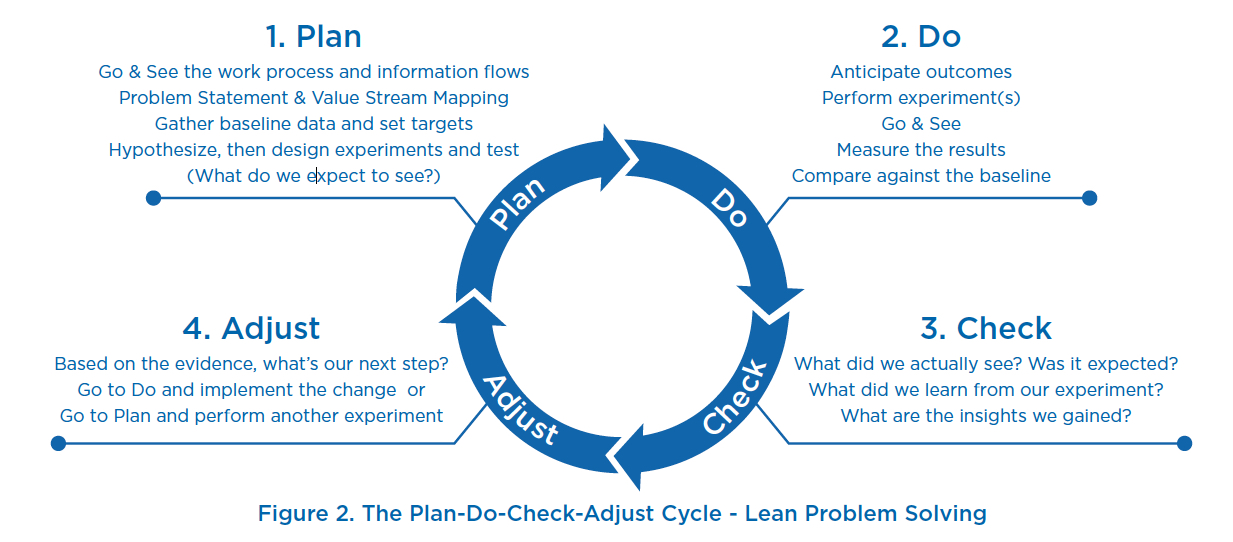

In lean, we engage those closest to the work to define a target state, determine our current status, measure the gap, and identify roadblocks and obstacles. We run a series of experiments to strengthen our understanding of cause and effect and validate which countermeasures effectively move the dial and achieve measureable results. This cycle of learning and discovery (referred to as PDCA – Plan-Do-Check- Adjust) is a process that is frequently repeated until it becomes embedded into daily work routines. Although it seems straightforward and relatively simple, it is wickedly difficult to accomplish!

Figure 2 illustrates the PDCA cycle – an educational cycle of trial and discovery. The initial step of the process is Plan which starts with going and seeing where the work is performed in order to fully understand the current situation from the perspective of customers, end users, and those doing the work. Emphasis is placed on facts (data) over opinion and discovering potential obstacles that threaten the attainment of a target state (where we need to be in terms of quality, delivery time, productivity, cost, and customer satisfaction). As we tighten our grasp of the situation, we develop experiments to validate our understanding.

In the Do phase, we run the experiment and compare outcomes with our expectations. Again, we place an emphasis on measuring what matters most to customers, end users and those doing the work. In Check, we reflect on the results of the experiment and learn. If the results are what we anticipated, we have validated our understanding of cause and effect and demonstrated that the countermeasures intended to spark improvements actually work! If the results show a gap still exists, then we still do not fully understand, and need to consider alternative approaches.

Finally, in the Adjust phase, we determine our next step on what we learned during Check. If we have identified a working solution, we make it part of the standard work process. On the other hand, if we have not discovered an approach that gets us to where we need to be, we enter another cycle of learning and discovering by repeating the PDCA sequence. The cycle is repeated until we attain the results required.

The power of PDCA or lean problem solving is in its scalability, neutrality, and methodology. PDCA works well with relatively simple challenges as well as complex enterprise-level problems. It is domain neutral and functions effectively in any discipline, be it IT, supply chain, finance, manufacturing, service, healthcare, science, or other fields. The structured methodology supports a way of thinking and mental framework of how we approach problems that drive higher quality analysis and more effective responses.

So where does technology fit into lean IT? The answer may surprise you: it fits in last! First we engage the people and provide the tools, training, and support they need to drive improvement to core business processes. Those people in turn focus on the process to enhance quality at the source and flow of value to end users and customers. Then and only then, do we implement new technology and/or reconfigure our current systems to enable and automate redesigned processes that focus primarily on effectiveness.

This is not easy work, but the payoff creates new levels of performance, a cultural shift, and a competitive advantage that are almost impossible to match. Happy people do great work. When people experience the positive feeling of solving problems at the root cause level (rather than repeatedly working around chronic problems), they experience radical shifts in performance, personal growth, and teamwork. When they have the tools and information they need to succeed, that’s where the magic happens. When it comes to technology, it starts with quality at the source and that means accurate, complete, and timely data.

If you want to succeed, data quality is not an option, it’s a necessity. The quality of your data will determine the quality of your information, which plays the defining role in the quality of your work. Lead with respect by creating work systems and processes that produce great work!

So Now What?

So what can you do to effectively address data quality problems and leverage lean IT to extract greater value from SAP?

Learn: start your lean IT journey by reading our first book Lean IT, Enabling and Sustaining Your Lean Transformation, and by pre-ordering the “How To” book The Lean IT Field Guide (available November 2015). Pre-order the book here.

Connect: engage with your employees by going to where the work is done to better understand the challenges they are experiencing and to see things from their perspective.

Involve: introduce lean process improvements by applying the PDCA cycle of experimentation.

Automate: only after you have engaged your people and improved core work processes, should you consider new technology and/or reconfiguration to automate and streamline newly improved processes.

As we discussed earlier, lean IT is all about engaging people, improving processes, and leveraging technology – always in that order. The sooner you begin to address the issue of data quality, the sooner you begin to realize the impact of high-quality actionable information.