This is Part 3 of Sequences, Behaviors and Integrating Adaptive Lean IT Systems – an updated article originally published in the Lean Management Journal in October 2015.

At the end of the day, all change comes down to altering our established patterns of behavior. Anyone who has attempted to make a lifestyle change (such as quitting smoking or eating healthier) can attest to how difficult this is.

It is interesting to note that most transformations tend to focus on training people in the new ways of doing things. We assume that if people know about a new (presumable better) way of doing something, they will automatically adopt it as their regular way of acting. Nothing could be further from the truth. If knowing about a better behavior caused people to change their actions and develop new habits, no one would be overweight, use tobacco products, or run on less than 6 hours of sleep!

We are all creatures of habit and become very comfortable with the way we’ve always done it, even when our routines become outdated, broken, and painfully frustrating. Why? Because it is really difficult to change the behavior of others or even ourselves. This resistance to change is a universal condition that, unless addressed directly and openly, puts all transformation efforts at serious risk.

MAKE/BREAK, CADENCE, & PREDICTABILITY

There are three factors you need to know about to effectively address this issue: make/break, cadence, and predictability. So what does it take to make or break a habit? I have confirmed it requires 40 days of practicing a new behavior before we can even begin to change old habits. At 90 days we have confirmed and strengthened the routine. At 120 days the new habit becomes deeply engrained as a part of our identity (how we see ourselves). At 1,000 days we have mastered the new behavior. Here’s the secret: the days must be consecutive! That’s right – if you miss a day, any day, the next day is Day One and you start counting from the beginning. I have personally used this approach to successfully affect change at both organizational and personal levels and it works.

Why is this approach so effective? People like routine and predictability – we are hard-wired to repeat what has worked before and to be skeptical of anything outside the conventional pattern. Most people drive to work using the same route, walk through a grocery store selecting the same items, watch the same TV programs, and go to bed at the same time – you get the picture. By enforcing a new routine and deliberately changing our behavior, we gradually provide the predictability and structure our human nature innately desires. When the changes make our work better, faster, less stressful, and prove to be more rewarding, that further reinforces the value of the routine and new habits begin to take deeper root.

As new work processes yield better results including more consistent quality, less rework, variability, and overburden, predictability of outcomes increases and we receive yet another dose of reinforcement – increased customer satisfaction!

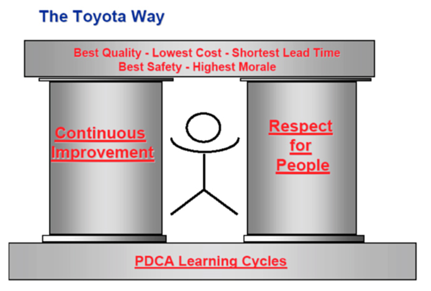

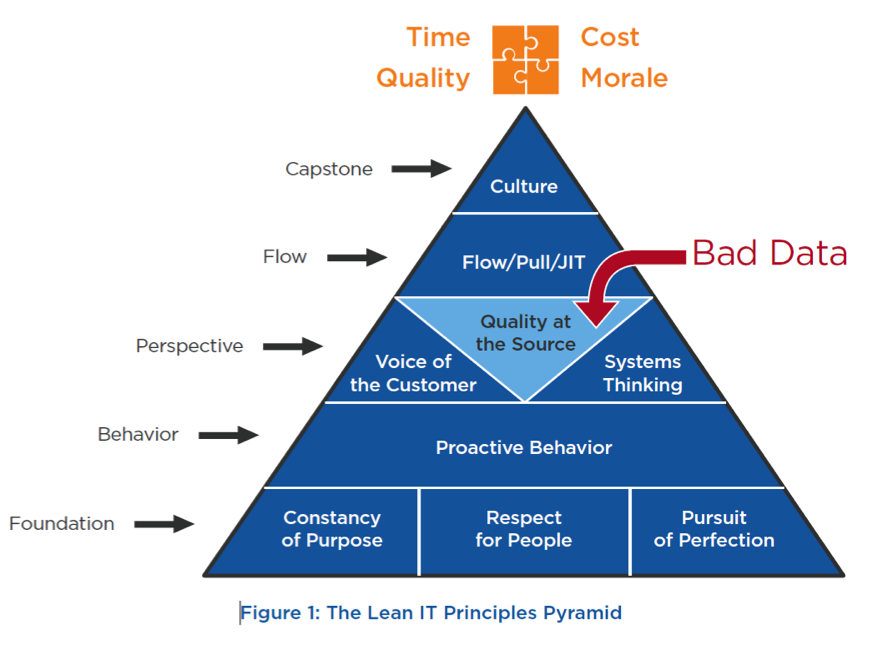

THE KEY SYSTEM – PROBLEM SOLVING

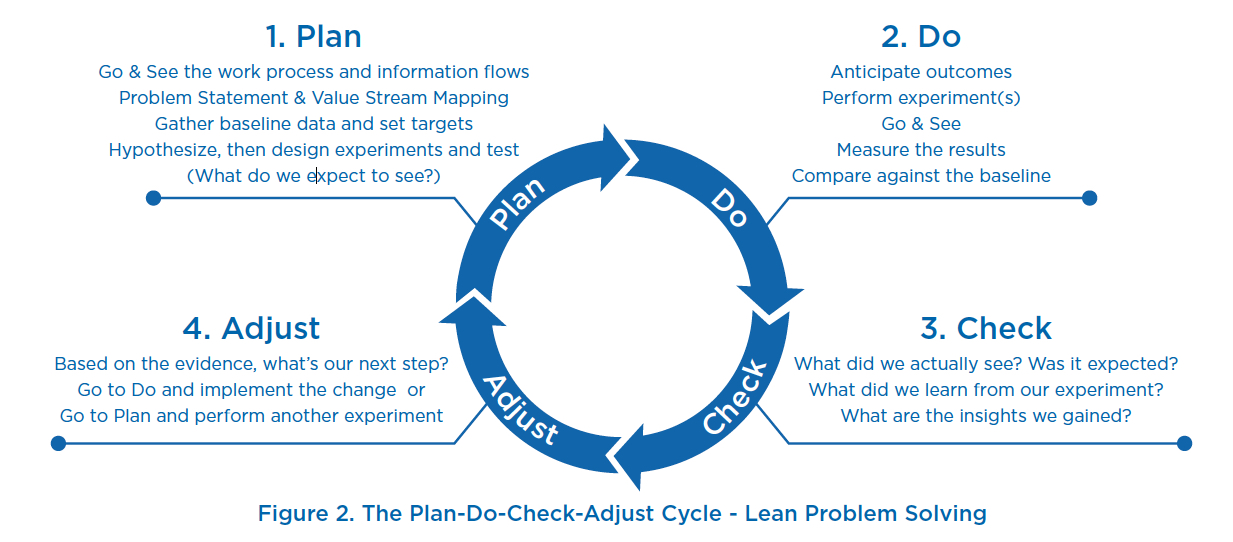

An example may serve to clarify this approach to creating new habits. Let’s assume you have introduced lean problem solving to your IT group as part of your transformation. People have received training in basic lean concepts including PDCA, A3, and root cause analysis. The assumption is that once people understand lean problem solving, they will use it in their daily work. This rarely happens. In most cases about 10% of your people will be self-starters and try to apply lean practices on their own. The vast majority of people attend the training and think, “That’s interesting…” and then go back to work using their normal ways of getting things done. They quickly fall back to their comfort zone, which excludes the ideas and tools shared in the training workshop.

Applying the make/break, cadence, and predictability concepts, we would include problem solving as an essential element of our daily team huddles and visual management system. On a daily basis, the team would be coached by responding to questions of inquiry designed to foster new ways of applying what was learned during the training on problem solving. The only way people learn lean is by doing lean!

In the final post of this series, we’ll explore the importance of work systems and sequencing to build adaptive Lean IT systems.