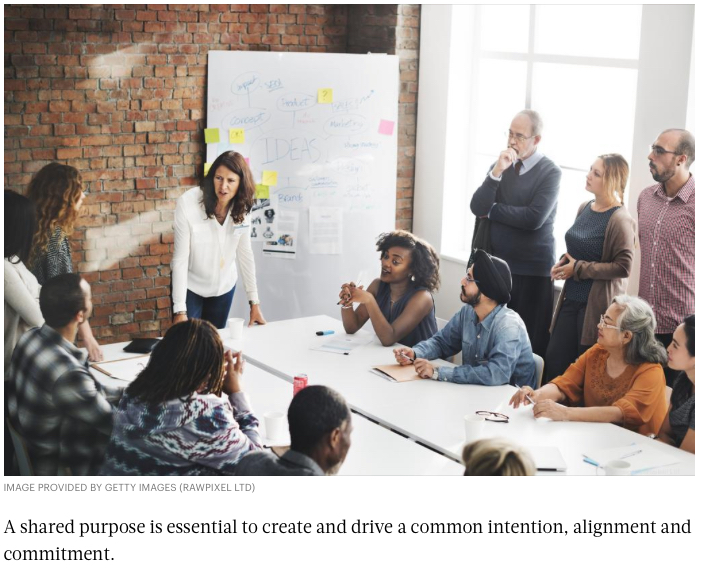

For decades, the lean community has been talking about the importance of creating and managing customer value across the value stream. A value stream is comprised of all the activities performed to create, manage and deliver value to customers. It includes all the wasteful and broken processes we have come to accept as inherent in the way the work gets done. A key player who focuses on coordinating and aligning the efforts of all pieces of the value stream is the value stream manager. Their goal is to get everyone working together and aligned toward the common goal of optimizing their entire value stream. I like to call this character the “mythical value stream manager” because they are described in books, but seldom seen in the wild – much like a unicorn.

This person is the master coordinator among silos, conflicting priorities, constrained resources and localized performance. No small task as most people focus on improving that small piece of work they have been assigned to and seemingly have control over. Can you really fault anyone for trying to make things better? Lean teaches us waste reduction, minimizing variation and addressing overburden as ways to improve flow. It’s no surprise that we attempt to apply these methods and tools to our own work first!

But herein lies the problem as well as the opportunity: local improvements do almost nothing to improve value stream performance and often negatively impact overall flow of the same value stream the team intended to improve!

Good intentions gone awry

I worked with a company whose Document Control Department decided to make improvements to their work processes with the noble intent of improving the flow of customer value. The company had been experiencing many delays in updating controlled documents (work instructions, drawing and technical specifications). The focus was on the time it was taking to process change requests and deliver updated and accurate documents to the appropriate work groups. The current process was taking days and sometimes weeks and crippling production and service levels in departments across the company. The team had received lean training and requested the help of a lean facilitator to guide them through an improvement effort.

After a focused 3-day effort, the team generated a series of countermeasures intended to address the blockers in their workflow which slowed or stopped their work. They rolled out the changes and measured the impact. Success! The total time it took from start to completion of their section of the value stream went for days to hours to minutes. The team held a party to celebrate the amazing results. They invited the departments whom they delivered they worked for. Surprisingly, no one attended!

A few people from the team were curious why no one came to the celebration. They paid a few people a visit and quickly found that the improvements they made had shifted work and problems to the very people they were trying to serve! Instead of impacting the flow of value across the value stream, they had optimized their flow by shifting the non-value added work to others. One team member shared, “What we discovered was that we had taken out the trash from our work flow and dumped on our neighbors’ front yard! To make matters worse, we then threw a party and invited them to share in the fun. Our efforts were well intended, but we completed screwed things up!”

Without a person focusing of the flow of the value stream, how can we expect leaders and front line contributors to coordinate their efforts to create improvements that ultimately impact the customer? When so many of our performance measures are focused on local results, how can we understand and support value-stream level outcomes?

Why we don’t have value stream managers

If we accept the importance of creating flow and the impact of a designated value stream overseer, then why are they so rare? There are many reasons (excuses) that come up including:

- It’s not my job to focus beyond my area of responsibility

- I’m busy just keeping my head above water

- My numbers are good, go pick on someone else

- I agree it’s important, but don’t step on my turf and try to influence my program

- My incentives determine my focus and my behavior

- Who needs more responsibility without authority? This is a fool’s errand!

Whether you agree with these points or not, they’re real in the minds of many.

What can we do about it?

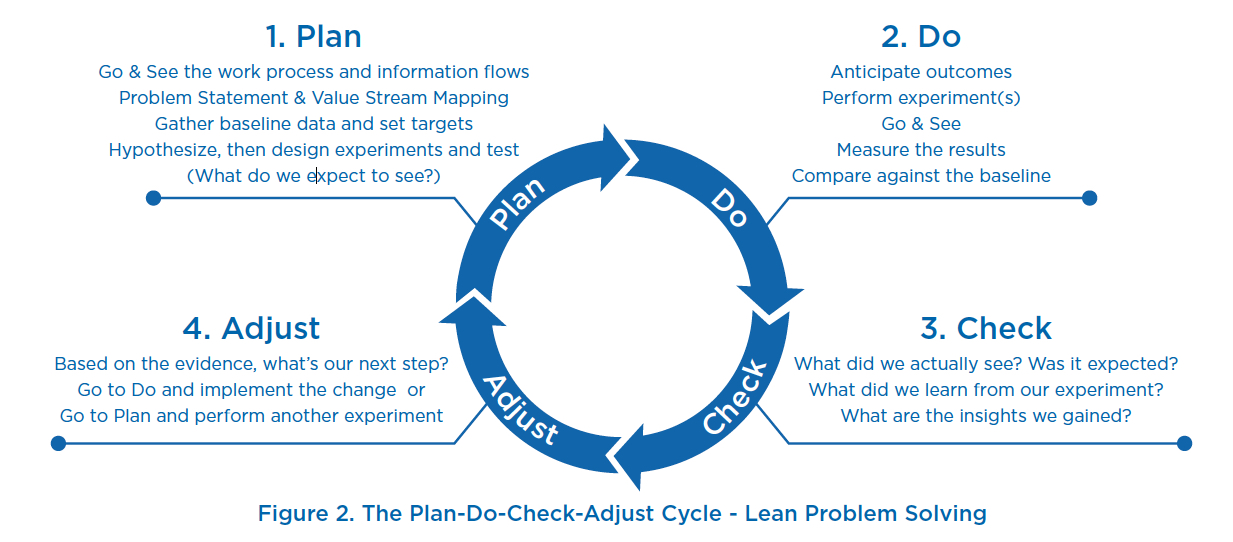

When leaders understand and appreciate the potential impact of a designated role focused on managing the value stream to improve the flow, quality and value at the speed of customer need, they may be willing to run an experiment. Create the role, provide clear goals and boundaries, socialize the change and gain support, gather baseline performance measures, run a trial for 90 days, re-assess performance by comparing to baseline, reflect on the results, share the learning, take your next step based on the learning. Sounds easy! It’s not.

- Identify a pilot area where you can test the effectiveness of value-stream focus

- Socialize the idea with every part of the stream (all the silos, vendors, departments, customers, managers and leaders (start with the leaders)

- Recruit a person who is willing to take on a temporary role of value stream manager – they’ll need a mandate to make things happen – this might be in the vocal support of the CEO or GM

- Plan on getting it wrong, learning from mistakes and making adjustments based on the data

Measures help people align

What works best to align people across the value stream is the use of value-stream level metrics that everyone is measured by. When everyone is playing off a common scoreboard, they shift their efforts from localized to global results. Here’s a few examples:

- Value stream percent complete and accurate

- Value stream cycle time

- Order fulfillment rate

- Returns

Give it a try

If you want to make a serious impact in your improvements, consider shifting your focus outward to a value-stream level perspective and find someone who is willing to take on the role of value stream leader. They’ll have to work with others based on what makes the most successful sense to the value stream rather than a single department or functional area. Approach this work as a learning experiment and expect many check/adjusts along the way. Good luck!

Until you shift to a focus on value-stream level performance, most improvement efforts are destined to miss the mark as they will shift waste and inefficiencies to another part of the business. Customers won’t feel the difference, even if you are celebrating the results! But what if your competition is focusing on value-stream improvements? From your customers’ perspective working with you, if things aren’t getting better, they’re actually getting worse.

I wrote this back in 2019 for the Lean Enterprise Insitute and a friend contacted me to share it again – Thanks Lisa!