by Ben Linders on Aug 27, 2015

Mike Orzen will talk about using core work systems to drive transformational behavior at the Lean IT Summit 2015. InfoQ will cover this event with news, Q&As and articles.

InfoQ interviewed Orzen about the benefits that organizations aim for when they adopt lean IT, why adopting and reinforcing new behaviors is essential to creating sustained change for the better, core work systems and work processes for IT organizations, and common missteps that organizations tend to make in lean IT transformations and how to prevent them.

InfoQ: Can you briefly describe lean IT for the InfoQ readers?

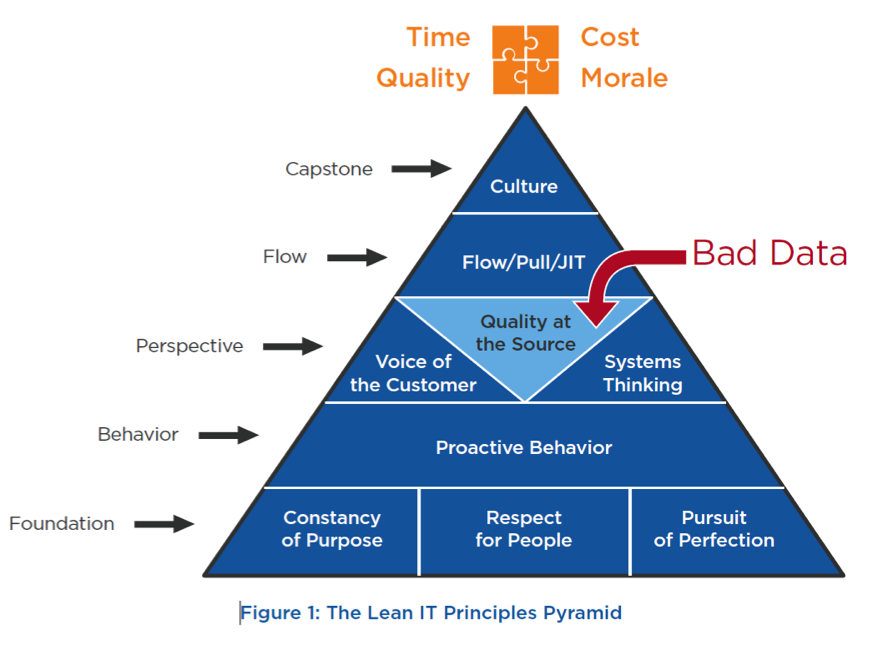

Orzen: Lean IT is the application of lean thinking to Information, Communication, and Technology. Lean thinking is a learning system made up of two key components: continuous process improvement and respect for people. Lean IT focuses on engaging IT staff in methodically improving IT processes and technology in order to deliver more value to its customers. Lean IT is all about people and technology enabling the entire organization to achieve great results through great behavior.

InfoQ: Which kinds of benefits do organizations aim for when they plan to do a lean IT transformation?

Orzen: In today’s world, business runs at the speed and agility of the underlying information flow. The benefits of lean IT are essential to make it possible for organizations to perform at high levels of operational excellence. There are many rewards: improved team effectiveness and productivity, greater return on IT spend, superior project performance (quality, user-acceptance, delivered functionality, delivery time, and total cost of ownership), higher levels of engagement and accountability, greater levels of trust, communication, and collaboration with the Business, recruitment and retention of IT talent, and the creation of a fun and rewarding IT work environment.

InfoQ: Can you elaborate why adopting and reinforcing new behaviors is essential to creating sustained change for the better?

Orzen: Most companies embarking on lean (whether in IT or another part of their business) tend to initially focus primarily on the tools (value stream mapping, A3, standard work, 5S, etc.). Tools alone fail to change the deeply engrained habits we all bring to the way we think about and perform our daily work. These paradigms tend to lock people into “the ways we’ve always done it” and prevent change beyond a superficial level, let alone breakthrough improvement. That is why well over 95% of lean transformation initiatives fall short of their stated goals.

No one likes change when it is done to him or her, but most people willingly participate when they are part of the creation process. When people are respectfully engaged to make real improvements to the obstacles they deal with everyday, given the tools, time, and support they need to test potential improvements, and coached to reflect and learn from the improvement cycle, we unleash tremendous energy and excitement.

Thinking alone won’t make this happen. We’ve all heard the maxim, “It is easier to act your way into a new way of thinking than it is to think you way into a new way of acting.” We lead with a bias toward action and that means changing behavior.

InfoQ: Your talk will be covering core work systems and work processes for IT organizations that want to become lean. Can you give some examples of this?

Orzen: Core work systems set people up for success by creating transparency, collaboration, and mutual trust among associates, supervisors, managers, and executives. These systems make it very clear what specific behaviors are expected of everyone. For example, a visual management system that clearly shows daily goals compared to actual performance highlights gaps between where teams need to be and where they are. When people know whether they are winning or loosing, they can make adjustments, communicate to stakeholders, request help, and escalate issues beyond their circle of control.

A visual management system creates the setting and context in which managers and executives visit the workplace on a regular, scheduled cadence to stand in the shoes of the people doing the work, understand their challenges, and actively coach, support and develop their people.

Another example is the problem solving system. I often work with companies that lack an approach for solving problems in a common, structured way. If you ask ten people how they go about solving a problem, you’ll get at least ten answers (sometimes more!). Without a united approach to the way people identify, define, understand, analyze, experiment, and ultimately solve complex problems, we tend to make guesses and try fixes based on unfounded beliefs and assumptions, often making matters worse!

When there is a common approach to how problems are defined, current conditions are analyzed, and potential solutions are developed and tested, the social fabric of an organization changes and drives new levels of engagement and results. PDCA, DMAIC, and Kepner-Tregoe are all examples of problem solving work systems. But the real key is not found in forms and templates, it is in the common language and behavior of team members as they encounter problems and opportunities for improvement.

Work processes are the methods, sequences, and steps we take to get the work done. When work processes are undefined or inconsistently applied, the effort required to perform work and the quality of the product or service are highly variable. Lean IT drives quality and as a result increases the flow of work. As this happens, the visibility and speed at which problems come at you are accelerated. In a lean IT work environment, work processes need to be stable, capable, standardized, and continuously improved. This is more of an aspiration than it is a final destination. As someone once said, “there is no finish line!”

InfoQ: What are the common missteps that organizations tend to make in lean IT transformations? Can you elaborate why do organizations tend to make these mistakes, and what can be done to prevent them?

Orzen: As I mentioned earlier, the most common misstep is the exclusive focus on lean tools. The most successful transformations are based on core principles, built through work systems, and adjusted through the tools. Another mistake is not engaging executives and managers appropriately and at the right time. Leaders, managers, and supervisors all have critical roles to play in a successful lean IT transformation. Sequence and timing are of critical importance and many organizations miss this.

A third oversight happens because lean is simple to understand yet deceptively difficult to successfully realize. The nature of information and technology, the interdependency of functional silos, working with the Business, and the complexity of technology, presents a very different domain with a vast array of unique challenges.

I have worked with organizations that had successfully introduced lean in areas such as manufacturing and supply chain, and then ran into a brick wall when they attempted to initiate a lean IT transformation. I believe the reason for this is the behavioral component of any transformation. Nowhere in business is this more pronounced than in IT. The very essence of technology is tools-based and siloed while the nature of the work is people-based and integrated – requiring high levels of communication, collaboration, and trust.

In IT, many organizations discover they need a roadmap in order to do the right things, in the right sequence, at the right time, and at the right pace. That was the impetus for our new book, The Lean IT Field Guide. Every transformation is situation-based, so each organization’s journey is unique – just as their infrastructure architecture, technology stack, and configuration is unique! That said, there are some common elements we find in all successful lean IT transformations.

InfoQ: If people want to read more about lean IT, where can they go?

Orzen: I can recommend five sources:

- our first book, Lean IT: Enabling and Sustaining Your Lean Transformation lays out the principles and foundational ideas of lean IT,

- our next book, The Lean IT Field Guide (available now for pre-order and on shelves November 2015) provides a roadmap for the work systems discussed),

- my website at com has information and resources,

- check out my twitter feeds (always on lean IT, lean, and related topics) @mikeorzen,

- and visit the new Lean IT Association site, this is an international non-profit group dedicated to supporting a high standard of lean IT practice. Full disclosure: I recently was appointed to their curriculum advisory board.

Lastly, I can be reached at mike@mikeorzen.com.