This post was written for DevOps.com

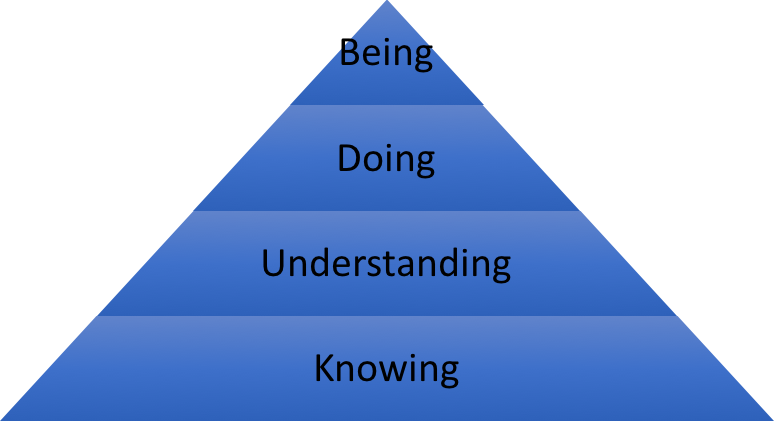

In the first bit to this post, “The Third Way of DevOps – From Knowing to Being,” we shared our thoughts on effectively applying knowledge to put the Three Ways of DevOps into practice. This blog explores a complementary dimension: How to build confidence when faced with a seemingly impossible task.

This is the all-too-familiar setting. You’ve seen an opportunity to improve things and genuinely want to do something about it. But you soon feel the clarity and anticipation draining out of you. First there’s the pressure of the day job. Then there’s the inertia of your co-workers, who are oblivious of or indifferent or hostile to your ideas. And finally, as if these concerns weren’t enough, you’re faced with the difficulty of unlearning old habits and developing new ones. In short, you don’t take action on what you have learned and know.

Self-efficacy

Expressed in the somewhat abstract language of the theories of Planned Behavior and Reasoned Action, there’s a gap between behavioral intention and actual behavior. A plausible explanation for the gap is low self-efficacy, defined as the conviction that one can successfully execute the behavior required to produce desired outcomes. It’s the belief we have in our own abilities, specifically our ability to meet the challenges ahead of us and complete a task successfully. This is a crucial precondition because investigations have shown that peoples’ behavior is strongly influenced by their confidence in their ability to execute that behavior.

If-Then-Else

So why doubt your ability to change? Well, when a change seems large, the gut reaction is to feel the need to come up with a project plan. Because a plan creates the confidence that when the steps are taken, the desired results will be achieved. Without a plan, we’d be irresponsible risk-takers. That’s how we’ve been taught to think. And rightly so—at least, in a predictable environment, where you can determine which steps will have which effects. If you work with IT, you are likely to think in terms of If-Then-Else. This is how we would like to believe IT always works. Predictably.

If-Then-Maybe

However—and this might be the biggest “however” you’ve come across for a while—things are not always predictable. Not unpredictable in the sense that it should have worked but something just went wrong because we didn’t do enough homework; unpredictable as in simply unknowable. Unpredictable as in possibly seeing a pattern of behavior in hindsight, but never having been able to predict it, let alone control it. Unpredictable as in “complex adaptive systems,” as they are referred to in the world of complexity thinking. It’s no longer If-Then-Else; the name of the game is If-Then-Maybe.

Complexity Thinking

Complex adaptive systems are all around us but if you’ve been used to thinking that things are—or could or should be—predictable, you tend not to see them for what they are: one of kinds of systems that exist in nature. The Cynefin sense-making framework describes systems in terms of five domains: obvious, complicated, complex, chaotic and disorder. Obvious and complicated are both predictable domains, where something in the complicated domain needs a bit of work to discover the predictability than when it is obvious. Complex and chaotic are unpredictable domains, the main difference being that something chaotic is dangerously unpredictable and therefore needs direct action. There is a fifth domain: disorder. You are in this domain when you don’t know which of the other four domains best describes the current situation. A word of warning: People’s cognitive bias will often lead them to think that they are in their usual domain, in which they feel most comfortable.

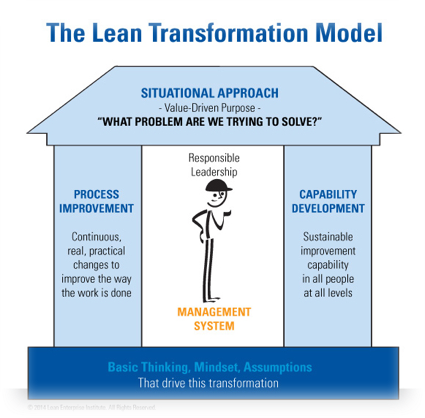

Step by Step

The way to introduce changes in complex systems successfully is to take it step by step. Because you can’t predict the results of a step, you have to closely monitor what effects—both desired and less so—each step creates. Then, based on your assessment of the new situation, you determine which next step to take. Rather than moving in a straight line toward a “to be” end state, you move each step to the “adjacent possible.” You make good use of the disposition of the system; in other words, where the energy is tending to flow.

No Big Answers, Just Little Questions

So, it’s not a case of looking for the big answer. It’s about a series of small questions. The Toyota Kata approach recommends asking ourselves (and others) these questions:

- What are we trying to achieve?

- Where are we now?

- What obstacle is now in our way?

- What’s our next step, and what do we expect?

- When can we see what we’ve learned from taking that step?

A key concept is that we should work towards the next “target condition.” This is an interim goal on the way to whatever we want to achieve. It just describes where you want to be next, not how to get there. It labels the future set of circumstances that lie just beyond our current level of understanding. It will typically have to be achieved between a relatively short period between a week and a few months; otherwise, it will be ineffective. How we will get there will emerge though the process of experimentation.

Stack the Cards in Your Favor

So the next time you feel inspired to make a (little) difference, don’t be discouraged by the prospect of having to think everything through in detail. This is often even contra-productive. The liberating realization that you can take things step by step, is good for your self-efficacy, increasing the chances of actually achieving results.

This article was co-authored by Mark Smalley.